We Identify and Prevent

Plant Equipment Failures and Errors

Tailored corrective plans and root cause determination

Forensic Consulting

Root Cause Analysis (RCA)

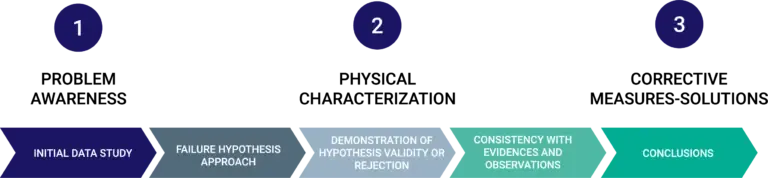

We are a recognized specialist in Root Cause Analysis (RCA), backed by expertise in forensic engineering methodologies—process analysis, data evaluation, inspection, defect assessment, and computational simulation—covering all stages of a comprehensive RCA process:

On-site visits and in-situ defect inspection

Analysis of historical data and Distributed Control System (DCS) signals

Material evaluation and laboratory testing

Failure hypothesis development and validation through FEA/CFD/CHT analysis

Definition and verification of corrective actions

Failure Cause Analysis – RCA

Failures such as accidents, loss of mechanical integrity, or premature degradation of service life often result from a combination of factors, including:

Design errors

Fabrication or assembly defects

Improper heat treatments

Operational misuse or abuse

Inadequate maintenance

Unexpected operating conditions

Inappropriate material selection

Root Cause Analysis (RCA) identifies the true origin of a failure by evaluating the behavior and influence of each potential factor through physical characterization and/or numerical modeling.

CADE provides comprehensive, multidisciplinary services for failure investigation, asset integrity evaluation, and forensic engineering related to failures in critical plant equipment, piping, and components.

Once a failure hypothesis is validated via RCA, corrective measures can be proposed, designed, and verified through CADE’s advanced consulting services, which may include FFS evaluations, laboratory testing, and/or in-plant trials.

Thanks to our extensive experience in asset evaluation, design validation, failure root cause determination, and equipment and process optimization, CADE provides external engineering consulting services as an independent expert in forensic investigations and due diligence processes within the industrial sector.

We have a particularly strong presence in the photovoltaic (PV) and concentrated solar power (CSP) sectors, where we have participated in the evaluation of assets and the analysis of catastrophic events at more than 20 plants worldwide.

Independent Engineering

Due-Dilligence

In decisions involving mergers & acquisitions, investments, or project development, a due diligence process provides a structured, in-depth analysis to assess return potential, risks, and overall feasibility—forming the basis for well-informed decisions.

Due diligence ensures objectivity and transparency by reducing uncertainties around the condition of the assets involved in a transaction.

CADE provides technical asset evaluations through detailed analysis that determines:

Current condition and performance of the assets

Remaining useful life, based on service history and usage

Compliance with relevant codes, standards, and regulations

This insight helps investors and stakeholders make risk-informed decisions, avoiding costly errors during negotiations.

CADE has extensive experience in the photovoltaic and CSP sectors, having participated in the evaluation of over 20 international plants, often in the context of catastrophic event investigations and asset reliability reviews.

Third Party y Peritaje

In complex industrial disputes, an impartial technical expert is often the only reliable way to avoid long, costly litigation.

With proven experience in the design, fabrication, construction, and analysis of special equipment and structures, CADE acts as an independent technical advisor in disputes involving designers, manufacturers, contractors, and operators.

CADE provides:

Objective and independent analysis

Forensic investigations and failure diagnostics

Technical evidence review and reporting

Written and oral expert testimony for court proceedings, arbitrations, mediations, or advisory panels

These services are particularly valuable in sectors such as Oil & Gas, Power & Energy, and other industries involving operational or catastrophic failure scenarios.