We Evaluate, Design, and Optimize

Piping Systems

We offer comprehensive solutions that ensure functionality, sustainability, and optimal system performance through advanced technical analysis and expert consulting.

Piping Engineering

Piping engineering is a fundamental pillar in the development of industrial engineering projects, particularly in process plants. Its proper application ensures efficient systems for the safe transport of fluids and gases, enhancing the operability and reliability of installations.

An optimal design not only ensures maximum space utilization, but also facilitates construction and installation, reduces maintenance costs, improves accessibility, and enhances overall plant performance.

We provide piping engineering services designed to meet the industry’s most demanding requirements, based on international standards such as ASME B31.1, ASME B31.3, and EN 13480.

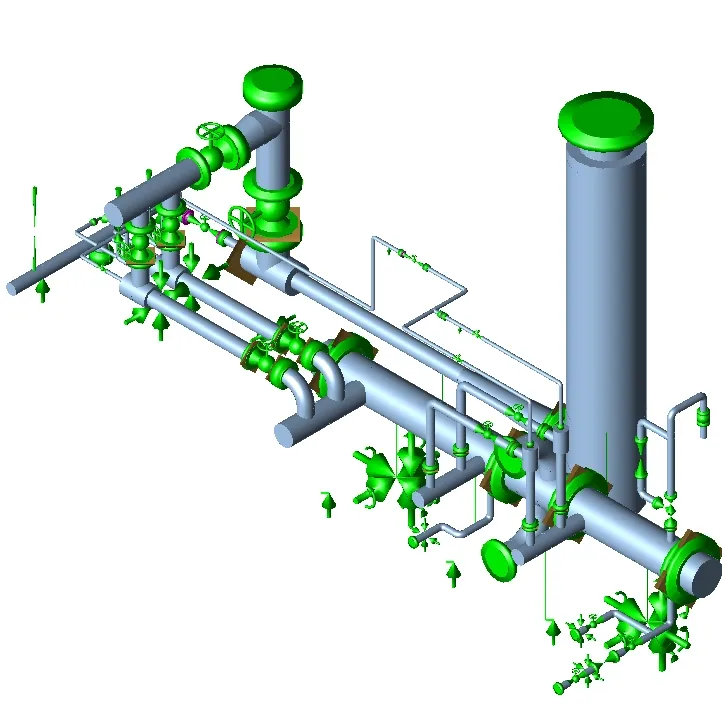

2D / 3D Piping Design

2D and 3D design is the foundation for an efficient and safe piping system, considering both functional and structural aspects. Our services include:

Hydraulic design: flow analysis, velocity, and pressure drop calculations to ensure efficient and safe fluid transport.

Technical specifications: accurate material selection, detailed drawings, and element rating definitions to ensure compliance with applicable standards.

Thermal management: evaluation and design of insulation systems to reduce heat losses and maximize energy efficiency.

Structured 2D/3D modeling: detailed 3D models that help identify clashes and optimize piping layout.

Mechanical design: thickness calculations according to international standards (ASME B31.1 / B31.3 and EN 13480) to ensure strength and durability.

Isometric drawings: construction documents including complete material take-offs and quantity listings.

As-Built design: updates to reflect the final installation conditions, essential for maintenance and future modifications.

Flexibility Analysis

Piping flexibility is critical for the safe and long-term operation of systems exposed to thermal and dynamic variations. We offer advanced analysis including:

Flexibility per international codes: evaluations according to ASME B31.1, ASME B31.3, and EN 13480, ensuring stresses remain within allowable limits.

Support design: definition of optimal support types and locations to guarantee structural stability.

Buried piping: specialized analysis to ensure system integrity under various underground loading conditions.

Allowable loads at connections: Verification according to WRC-107, crucial for pump and static equipment connections.

Advanced dynamic analysis:

Modal analysis: identification of natural frequencies to avoid resonances.

Harmonic analysis: evaluation of system response to periodic loads.